3D Resin Printing 00 Model Trains #2

The first 00 gauge model train wheel print... failed, but that's OK

My First Fully Custom Print

I printed the bundled test models without issue. I also printed a figure for someone else using default values. All fine. But my 00 wheels are much smaller and thinner.

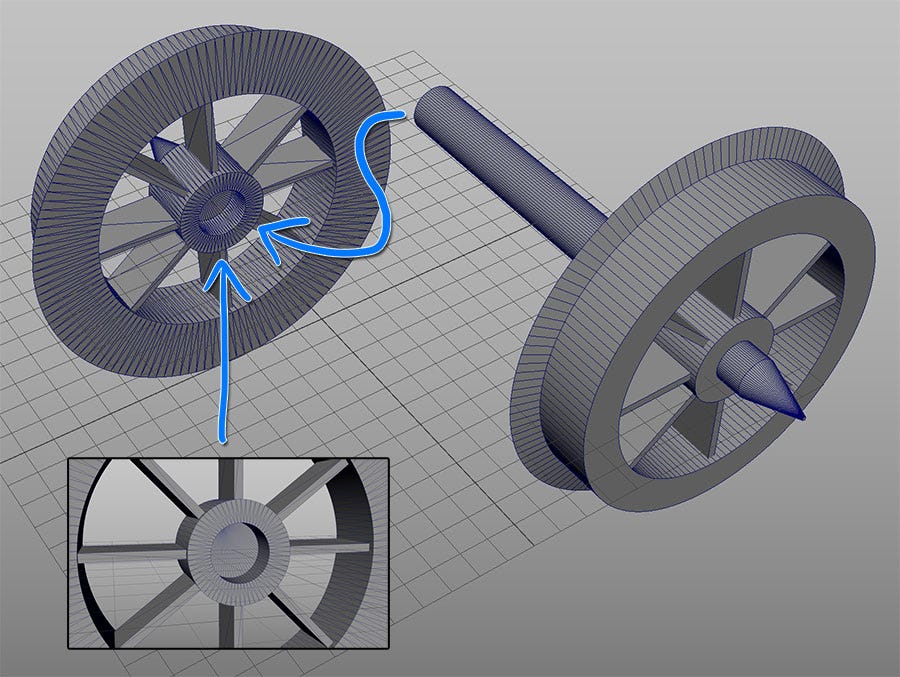

Reminder, this was the mesh being printed:

There are no pictures of these failed prints from the vat. When it happened I knew I would have to drain the vat and scrape the FEP. Neither of which had been done before, so it wasn’t a total loss. I’m now confident in cleaning the machine. Which seems to be a hell of a lot of effort for resin printers.

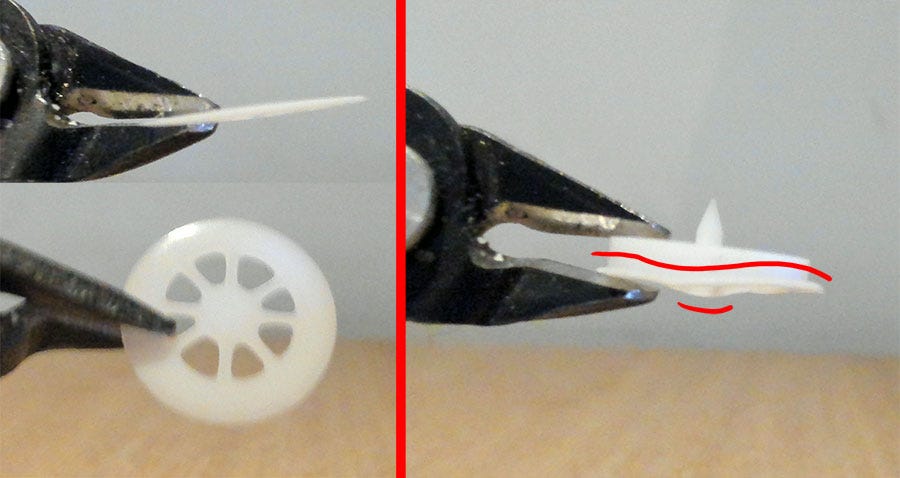

This is what failure looks like…

A couple of supports were stuck to the plate but most had broken off. As too had the axle, which should have been attached to the right wheel. The right wheel also sunk a little in the middle, where the axle was mean to be. Or maybe it only looks like it sunk because the flange is warped?

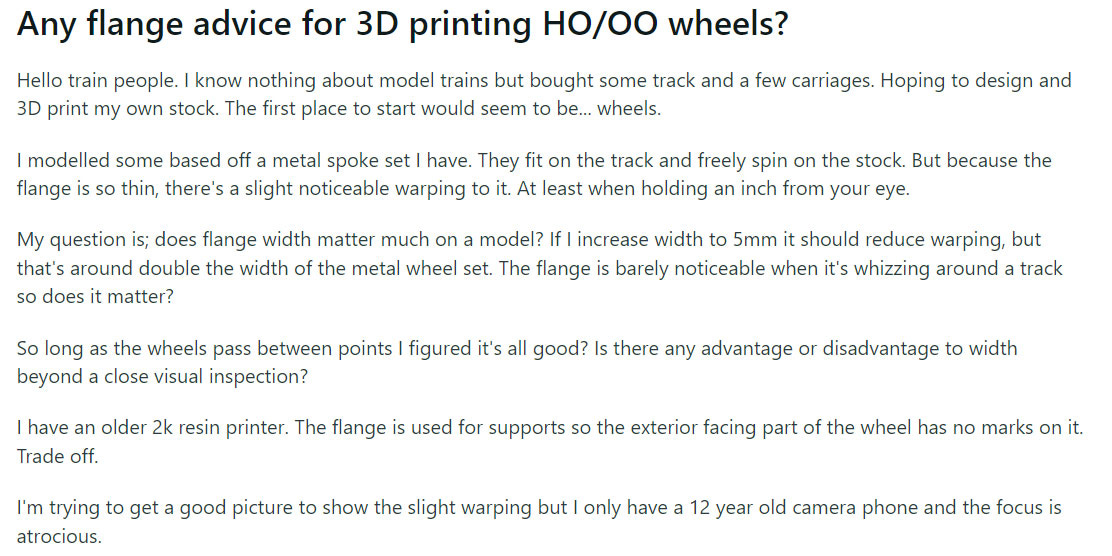

Bigger supports may help straighten the flange, but it feels too thin regardless. On a model railway Reddit page, I asked if flange width would affect anything in regards to cornering. Great idea. Ask Reddit!

…and the insults, all top rated:

There’s a reason kids haven’t been interested in model trains for decades. No innovation and boring, morbidly obese losers who think they know everything.

I’m not trying to steal your hobby from you or put your little eBay shop out of business. Although, thinking about it, I might just do that now? Because my prints will be a hell of a lot more creative than the mundane garbage that lot will ever create.

No one uses forums anymore, which explains why everyone is so stupid. I tried looking for guidance on what the problem could be but kept being directed to the paedo platforms of Reddit, Discord and YouTube. The latter being of zero value these days. It’s all e-begging videos providing non-answers and 20 minutes of gibberish to reach maximum ad revenue.

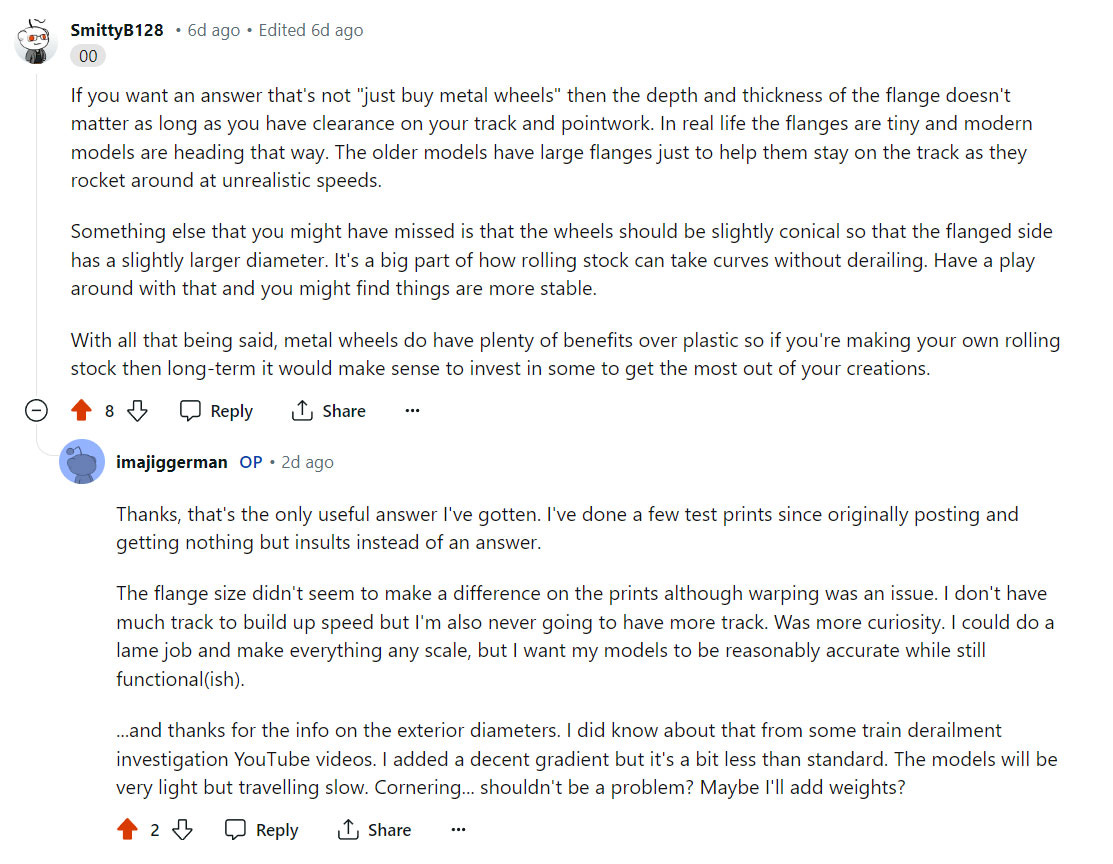

Eventually some very nice people did respond on Reddit. Funnily enough, they had almost no up votes despite answering the actual question:

Thanks you.

So flange depth doesn’t seem to be a massive issue. It could be 0.1 mm, or larger, instead of 0.03 mm. The train should still move through points and corner without issue. Awesome.

Consensus withing the 3D printing community seems to be

Add more supports than necessary to everything

Light supports are useless

Auto support in Chitubox is mostly useless

I used small supports because the wheels are tiny. They weigh almost nothing so why would I need larger supports? Auto support was used because I wasn’t confident in adding my own. Time to learn.

The pancaked wheel on the left was likely stuck to the FEP because the supports weren’t strong enough to pull it off. It’s flat because once it hardened and broke from the supports, no resin could get underneath to create another layer. This layer just hardened further through more light exposure.

Now I have a little experience and some useful information, let’s get it fixed and printing again. Working from home has zero downsides.

Printing Issues to Address

Here’s what I’m thinking…

Supports are too thin.

Use only medium or heavy supports and more of them. Perhaps use light supports for the spokes because they’re so thin? Making sure these small supports anchor to the medium/large supports.

The wheels are printing flat with supports attached to the inner side. This width of the spokes are printed by their thinnest sides. So I expect they will need some support? Maybe add slight supports for a couple of the spokes and see how the model is affected.

Manually place supports.

Auto support is sent to banworld.

If supports continue to be a problem, switch to PrusaSlicer. If only to create supports and export the model back to Chitubox for printing. I’ve heard lots of good things about PrusaSlicer’s auto support but no program can replace an experienced human.

More supports.

Maybe 8 around the edge of the wheel? Close to the edge of the flange to reduce warping.

A heavy support attaching to the bottom of the axle and inner cavity area, depending on mesh. This should counter any sagging. It does mean the axle might not fit cleanly in to the cavity. The axle tip will need sanding and my rotary drill will have to clean out the cavity.

I might redesign the axle join section completely. Once I get consistent, successful prints!

If failures persist…

Tweak Chitubox print settings. Maybe:

Reduce or increase exposure time

Tweak layer height

Lower lifting speed

…everything else

Mesh Enhancements

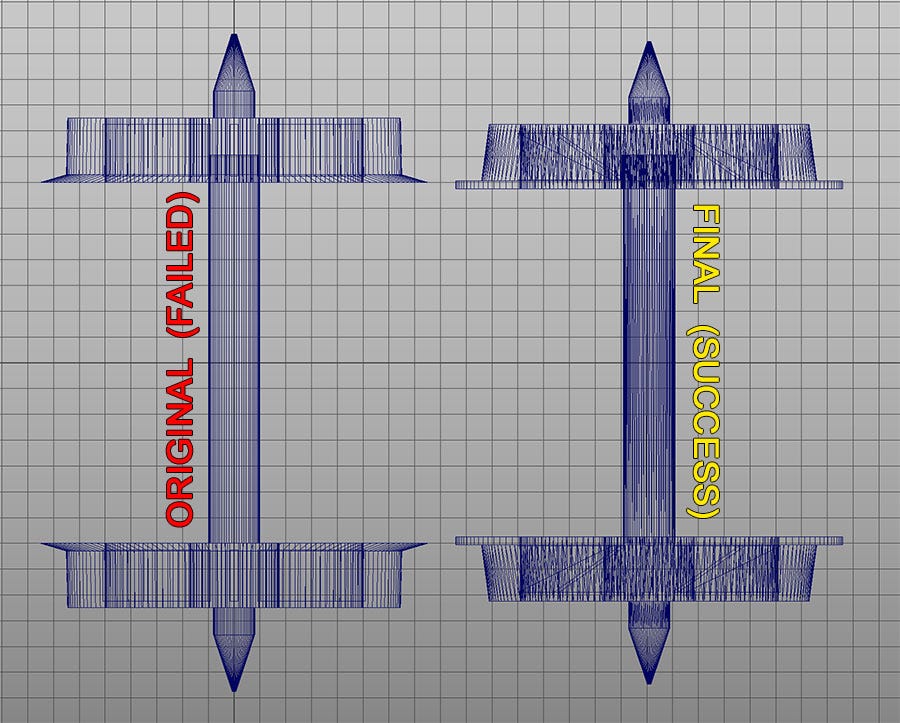

There were 2 improved versions of the original mesh (versions 1, 2, 3). Both were printed, but I only kept the 3D files for the final version. The other was useless and I overwrote it without thinking.

Version 2 enhancements:

The Flange taper was removed and squared off. The failed prints looked far too thin even though measurements matched my metal wheels. I’m also trying to lessen warping on the flange.

Diameter of the outer wheel was reduced, creating a greater angle. It looked too square. perhaps this will improve cornering too?

More supports and larger supports were added. Manually placed!

Spoiler; printed perfectly with these supports.

Version 3 enhancements:

Tip to tip length was slightly reduced. Version 2 printed fine but felt quite tight while fitting wheels in to a wagon. There was a decent amount of flexing in the axle, as expected, so I wanted to lessen forces on the axle joints.

This was performed at middle axle level. This means there would be more slightly more horizontal play for trains moving left to right.

I don’t think it would affect anything, but my v2 print had a little less play than my metal wheels. This should add more, not that it needs fixing. So long as the train moves through points without derailing, I’m happy.

Cavity for the axle was increased by around 0.1 mm. It was really tight in v2 and needed to be ever so slightly larger. Too large and the wheel angles would be different.

Diameter of the outer wheel was further reduced, creating an even greater angle.

The gap between the

How did they print?

That worked.

Mostly.